Roof Painting and Coatings

With years of specialized experience, a steadfast commitment to safety, and a portfolio of savvy, cost-effective solutions, Markley’s Precision Company (MPC) stands as your premier partner for comprehensive roof painting and coating, servicing Ohio and nationwide.

At MPC, we understand that your roof is more than just a structural component; it’s a vital investment in the longevity and safety of your industrial or manufacturing facility. With the relentless challenges posed by weather, temperature fluctuations, and time, safeguarding your roof is not just an option—it’s a necessity. That’s where we come in.

We specialize in:

Our process is thorough, from initial assessments and infrared surveys to final coatings and sealings, ensuring that every inch of your roof is prepared to withstand the elements and the test of time.

Let us help you enhance the longevity, safety, and aesthetic appeal of your facility, all while optimizing your return on investment. Welcome to the pinnacle of roof protection—welcome to MPC.

Send Your Request And Get A Free Quote

Why Choose Us?

Diverse Coating & Painting Arsenal

Versatile Project Capability

Quality Finishes and Durability

Accident Free Safety Record

Best-In-Class Warranties

Zero Downtime Process

Safety & Environmental Commitment

Nationwide Service Coverage

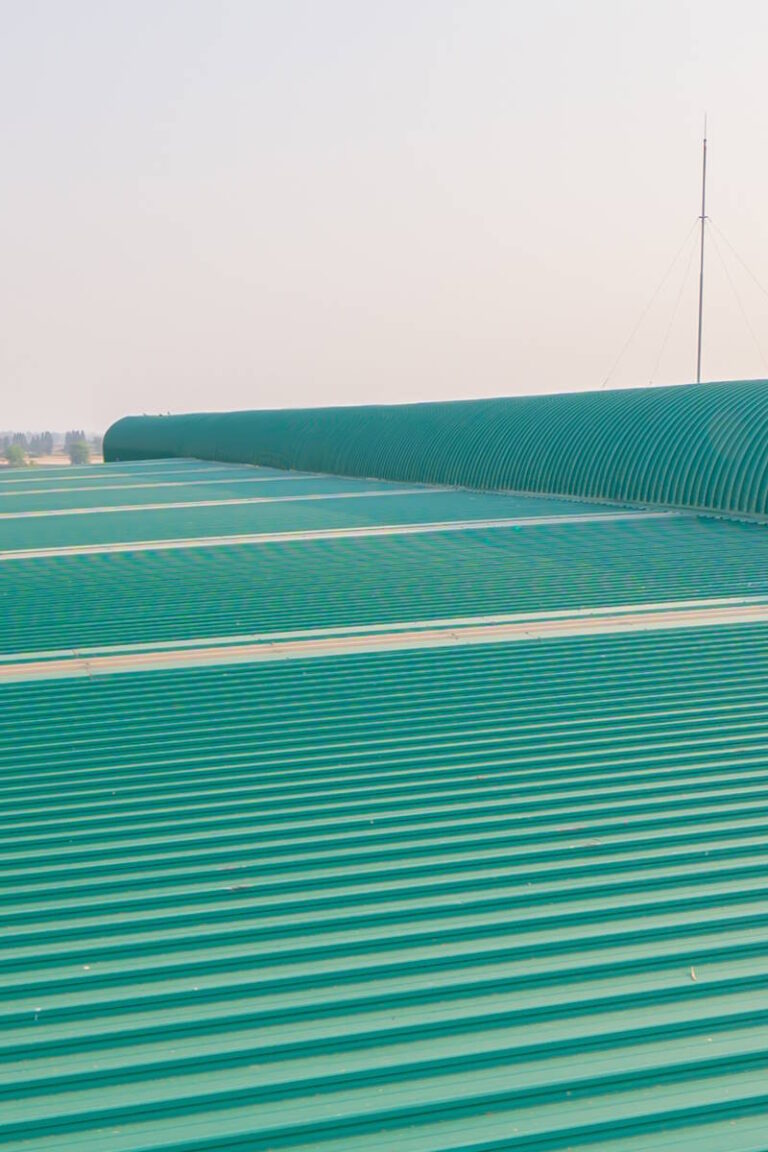

Metal Roof Painting

The Challenge:

Exterior metal roof coatings and finishes are subjected to environmental conditions including exposure to UV rays, sun damage, rain, and temperature fluctuations, which can range from extreme heat to extreme cold. These factors can significantly impact the durability of the current coating or finish.

Exterior metal roofing and aluminum structures are particularly vulnerable to these harsh conditions, especially during seasons like spring and fall when drastic daily temperature swings can cause severe expansion and contraction. This may lead to the existing coating loosening and potentially result in premature coating failure.

Our Solution:

We opt for lighter colors such as whites and light tans can aid in reflecting heat, thereby keeping the surface cooler and mitigating these drastic temperature changes. This not only contributes to energy savings by reducing the need for cooling during warmer months but also extends the life of the coating.

Utilizing a urethane coating, especially in conjunction with a white hue, is an excellent choice. Urethane coatings are renowned for their superior color and gloss retention, enhancing the aesthetic appeal while offering a more durable solution due to their long-lasting gloss and color.

Benefits of Metal Roof Painting

Enhanced Cleanability & Cost Efficiency

Glossy surfaces, like those achieved with glossy white urethane alkyd coatings, are easier to clean compared to older, duller surfaces, reducing cleaning time and maintenance costs.

Extended Roof

Longevity

Extends the roof's service life, often through warrantied maintenance services, saving on reinstallation costs.

Safety Hazard

Reduction

Eliminates safety hazards from old, peeling paint or corroded areas.

Improved Energy

Efficiency

Lowers energy costs by improving building insulation, particularly beneficial during warmer months.

Regulatory Compliance Assurance

Ensures regulatory compliance with FDA, USDA, EPA, and other standards.

Property Value Enhancement

Increases property value, making painting a wise investment for enhancing ROI, whether for selling or renting out property.

Flat Roof Coatings and Membranes

For flat and low-slope roofs, we provide a Silicone Roof Coating solution. This coating is a fully adhered, seamless layer that is applied directly over the existing roof substrate. It acts as a restoration membrane, effectively preserving the integrity of the current roof while avoiding the expenses associated with its removal and replacement.

Silicone Roof Coatings are designed to protect your building against water infiltration, UV damage, and temperature variations. Their seamless application ensures a watertight barrier, extending the lifespan of your roof and enhancing its overall performance.

Additionally, this type of coating can significantly improve energy efficiency by reflecting sunlight and reducing heat absorption, leading to lower cooling costs during warmer months.

By choosing a Silicone Roof Coating, you’re investing in a cost-effective, long-term solution for maintaining and enhancing your flat or low-slope roofing system.

Variables Influencing Silicone Roof Painting Costs:

- Wet insulation amount

- Roof’s current condition

- Roof pitch or slope

- Size and height

- Accessibility and limitations

- Local atmospheric conditions

- Material cost

- Warranty options

Benefits of Silicone Coatings for Flat Roofs

Cost Efficiency

One of the most significant benefits of opting for a silicone roofing membrane is the potential for substantial cost savings—up to 50% compared to removing and replacing the roof.

Applicability Over Multiple Roof Assemblies

Silicone coatings are considered a maintenance item and can be warrantied even over multiple systems, offering flexibility and longevity.

Fast Turnaround Time

Our silicone roof coating process is significantly quicker than a full roof replacement, approximately 60% faster, minimizing disruption and reducing the risk of interior damage.

Energy Savings

Switching from a darker colored roof, such as black EPDM, to a white silicone roof can significantly reduce cooling costs during warmer seasons.

Warranty Options

We offer a variety of warranty systems, including 10, 15, and 20-year options, providing peace of mind and long-term protection for your investment.

Our Process to Determine if Your Roof Qualifies for a Silicone Coating Option

First, we conduct an infrared survey of your existing roof system to ensure it is dry. This initial step is crucial for assessing the suitability of your roof for a silicone coating.

We meticulously assess the condition of flashings, seams, pipe boots, drainage systems, and other protrusions to ensure they are in good shape.

Typically, we collaborate with a local roofing contractor to address any repairs beyond what a simple sealing could fix. This approach ensures that repairs are executed correctly, providing our clients with a superior final product.

We remove gravel, debris, and other materials that could hinder our ability to thoroughly prepare and paint the roof. This includes an SSPC SP1 solvent cleaning with a 3500 – 5000 psi pressure washer and usually an eco-friendly degreaser.

Priming may not always be necessary, but if it doesn’t pass an adhesion test, we proceed with it. We ensure a stronger bond by striping all seams and flashings with primer or a fiberglass-based primer/sealer.

Your roof will be coated and sealed with a high-quality siliconized roof coating, typically applying 1-2 coats depending on the warranty desired.

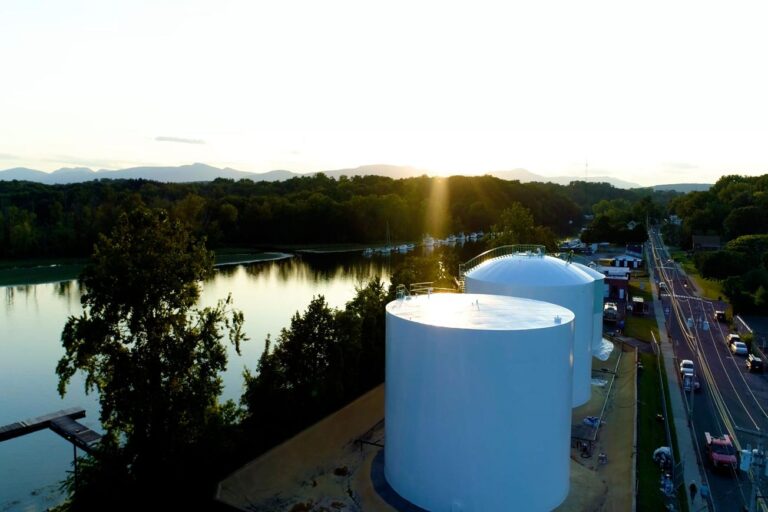

Agricultural and Silo Roof Painting

The Challenge:

Roofs play a pivotal role in safeguarding the contents of any building, a responsibility that becomes even more crucial for agricultural structures such as grain silo roofs, fertilizer towers, and seed tanks.

The risk of spoiled or contaminated agricultural products can lead to significant financial losses for businesses and agricultural cooperatives. Employing a skilled contractor to regularly seal and waterproof these roofs can substantially mitigate the risk of such damages.

Our Solution:

For waterproofing and sealing silo bin roofs and other flat roof areas, we utilize asphalt-based urethane elastomer coatings with a non-slip aggregate for added safety. For coned or sloped steel roofs, we recommend an epoxy high-solids urethane coating system that offers excellent protection, maintaining the roof’s integrity. Adding aggregate can enhance grip, improving safety.

We also make use of Elastomeric Coatings that are notably more flexible than standard coatings, designed to adapt to seasonal and temperature changes while preserving their adhesion and bond to the roof. This flexibility makes the coating exceptionally resistant to chipping and cracking. It can be applied to both metal and concrete roof substrates, effectively sealing pre-existing cracks and can be applied in freezing temperatures if necessary, offering year-round protection.

Our Process of Painting Silo Roofs

Our standard procedure for painting or coating agricultural and silo roofs involves several key steps.

Following these steps results in a robust, waterproof membrane that will protect your agricultural roofs against the elements for years to come.

This crucial first step may include hand and power tool preparation, utilizing pressure washers and solvent/degreasers for cleaning, or abrasive blasting to remove old coatings and contaminants. This ensures a clean, sound substrate for optimal bonding.

Applying mortar or 100% solids epoxy patching as needed to seal any significant cracks, holes, or chips in the substrate, preparing it for the coating process.

An epoxy or suitable bonding primer is applied to the prepared surface to enhance the adhesion of the topcoat.

Addressing roof protrusions, seams, gaps, and smaller voids with seam seal tape, an appropriate sealant, or a layer of scrim cloth or mat reinforcement embedded in the coating. This step ensures a watertight seal.

Finally, two coats of the selected topcoat are applied, creating a seamless, durable, and waterproof membrane.

Why Trust MPC for Your Roof Painting Needs?

Expertise and Experience

Unwavering Safety Commitment

24/7 Flexible Service

Cost and Time Efficiency

One-Stop Solution

Our Roof Painting Techniques & Equipment

Preparation is Key:

The most crucial step we take in the coatings process is preparation. Without proper cleaning, etching, and preparation of the substrate (surface), the coating, regardless of its quality or manufacturer, is destined for premature failure due to inadequate prep work.

Surface Preparation Options:

We tailor our surface preparation techniques to meet our clients’ needs, preferences, and budgets.

Options include traditional sandblasting, “dustless” or wet blasting, dry ice blasting, laser blasting, shot blasting, bristle blasting, Ultra High Pressure water blasting, both cold and hot water pressure washing, soft washing, and manual hand prep.

Adaptable Sandblasting Operations:

Our sandblasting operations are versatile, allowing us to work in complex environments. This includes highly active facilities where respiratory safety, electrical conduits, live gas lines, and ventilation are critical concerns.

Advanced Equipment for Complex Projects:

We utilize containment scaffolding, containment tarps, dust collectors, industrial vacuums, swing stages, aerial baskets, and aerial lifts to tackle complicated projects efficiently.

Coating Application Equipment:

Our arsenal includes a variety of painting equipment such as airless spray pumps, air-assisted spray pumps, conventional spray pots, agitators, plural component spray equipment, and hydraulic spray pumps.

Experienced applicators wield every spray gun or brush, ensuring professional and effective application for any painting project.