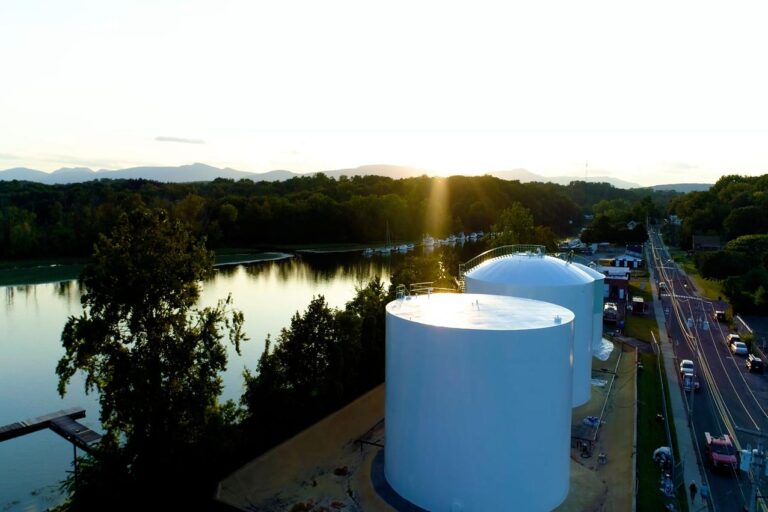

Water Tank Painting and Linings

MPC offers expert water tank painting services across Ohio and throughout the United States, ensuring tanks everywhere can benefit from enhanced durability and protection.

Applying a fresh coat of paint to water tanks is an excellent method for preserving and prolonging their service life. This applies equally to newly installed tanks and those that have been in operation for several years. A fresh coat of specialized paint can significantly increase a tank’s lifespan, safeguarding it against various environmental factors such as weather conditions, contaminants, and wind.

Our process of tank painting typically includes sandblasting to prepare the tank’s steel surface for a new coat. Our company stands out by owning advanced equipment for this purpose, rather than relying on rentals, ensuring efficient and high-quality restoration.

Adhering to both federal and state regulations to prevent the spread of debris is crucial. During the cleaning and recoating phases, we construct a containment system to manage hazardous materials like lead and chromium dust, as well as used abrasives. We employ dust collectors, HEPA filters, and various large-scale industrial vacuums, prioritizing the safety of our team, the work site, and the nearby community

Send Your Request And Get A Free Quote

Why Choose Us?

Nationwide Tank Painting

Over 5000 Tanks Restored

Preferred Contractor

Accident Free Safety Record

Best-In-Class Warranties

Zero Downtime Process

100% Eco-Friendly

Anywhere In The USA

Our Water Tank Painting & Lining Process

We start by comprehensively understanding the client’s unique needs. This includes discussing their objectives, budget, desired timeline, permissible downtime, specific concerns, and the overall importance of the project to their operations.

Our team delves into identifying whether there is an existing issue, a potential problem, or symptoms indicating future concerns with the water tank. This involves a thorough examination to understand the root cause and the extent of any issues.

Safety is paramount in our process. We conduct a Job Safety Analysis (JSA), assess any confined space concerns, implement lockout-tagout procedures, and develop emergency action plans. Special attention is given to lead abatement, fire prevention, and adhering to any additional plant-specific safety requirements.

Based on our findings and the client’s needs, we customize a solution. This involves selecting the appropriate lining system or other solutions that align with the client’s goals. We then develop a detailed scope of work, identifying the necessary equipment, manpower, and materials required to execute the project within the parameters set in the previous steps.

With all the information and preparations in place, we present a comprehensive plan to our client. This plan includes a step-by-step approach on how we intend to address their water tank painting and lining needs, ensuring transparency and alignment with their expectations and requirements.

Benefits of Water Tank Painting

Cost Saving

Corrosion Prevention

Health & Compliance

Durability

Types of Water Tank Liners We Provide

Tank liners are crucial for protecting tanks from damage and contamination. Here’s a look at some types we provide:

Epoxy Linings

These are created from epoxy, a material known for its chemical resistance. Epoxy linings are robust and can withstand high temperatures. Being moisture-tolerant and solvent-free, they are an excellent choice for water tanks.

Polyurethane Linings

Offering a balance in flexibility, polyurethane linings are more adaptable than many alternatives, making them suitable for concrete structures.

Vinyl Ester Tank Liners

Constructed from vinyl, these liners excel in preventing chemical infiltration. Their high resistance to temperature and chemical damage makes them a preferred choice in chemical industries.

Polyurea Tank Liners

A relatively new addition in the tank lining industry, polyurea is applied as a gel-like substance using special spraying equipment. Known for its exceptional flexibility and strength, polyurea can stretch up to 900%. It's designed in various formulations for different applications and is notable for its abrasion resistance and solvent-free nature.

Cementitious Liners

These include epoxy and polymer-modified cementitious linings. Commonly used in concrete tanks for water treatment and chemical containment, they are effective for waterproofing and are ideal for structures submerged in water.

Zinc Tank Liners

Made from zinc silicate, these liners are anti-corrosive and their composition includes high levels of zinc dust. They provide cathodic-like protection, similar to galvanizing processes. Zinc liners are non-porous, making them a bit challenging to clean but effective in containing chemicals. They are resistant to solvents, making them suitable for solvent tanks, though they are less effective against strong acids and bases.