Commercial & Industrial Sandblasting Services in Ohio & US Wide

Our commercial and industrial sandblasting services span a wide range of types of surfaces.

Our contractors tackle a vast array of challenges, including above-ground storage tanks, structures, fuel tanks, heavy machinery and equipment, and contribute to the vital arteries of our land, including commercial buildings, bridges, and structural steel.

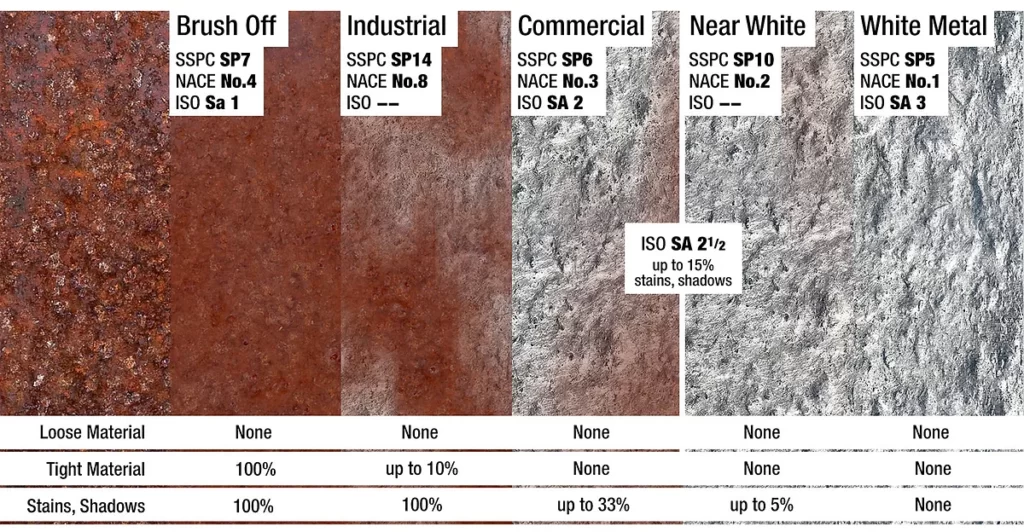

Whether your task demands compliance with NACE, ISO, or SSPC, our company sets the gold standard for blasting equipment to meet your project’s blasting and coating specifications. From traditional blasting to innovative laser blasting, dustless blasting, soda blasting, non-abrasive dry ice blasting or HP water-jetting, your project deserves nothing less than our tailored, top-of-the-line approach.

Our choice of zero-silica, 100% eco-friendly blasting media isn’t just about following regulations – it’s a testament to our commitment to sustainable practices. So, you’re not only left with beautifully prepared surfaces but also a cleaner, greener impact on the world. Moreover, our stringent adherence to OSHA, EPA, and DOT regulations is non-negotiable, assuring you that every job we execute is done so with the utmost safety, environmental mindfulness, and complete regulatory compliance.

Your project isn’t just another job to be done; it’s a canvas, and we’re here to create a masterpiece out of it!

Get A Free Quote

Our Clients

Why Choose Us?

Broad Surface Sandblasting Expertise

Zero-Silica, Eco-Friendly Media

Precision Exceeding Industry Standards

Customized Blasting Solutions

Innovative Dry and Dust-Free Methods

Zero Damage Promise

Regulatory Compliance Assurance

Anywhere In The USA

What Our Customers Say

Some of Our Commercial & Industrial Sandblasting Applications in Different Sectors Include:

Infrastructure and Construction Sector

- Oil and Gas Industry: Cleaning storage tanks, pipelines, and processing equipment.

- Nuclear Power Plants: Cleaning and decontamination of critical components.

- Shipbuilding and Repair: Stripping paint and coatings from ships, preparing surfaces for new coatings, cleaning decks and hulls.

Manufacturing and Engineering Sector

- Steel Fabrication: Preparing steel surfaces for welding, painting, or galvanizing.

- Foundry Work: Cleaning castings after mold removal.

- Heavy Machinery and Equipment: Removing rust, paint, and contaminants from large machinery.

- Aerospace Industry: Cleaning and preparing aircraft parts for maintenance or paint.

- Automotive Industry: Removing paint and coatings from car parts before remanufacturing.

Commercial Sector

- Surface Preparation for New Coatings: Removing rust, paint, and other contaminants from a surface before applying a new coating.

- Concrete Cleaning and Texturing: Cleaning concrete surfaces and creating a textured finish. This can be used for slip-resistance on floors or to create a decorative effect.

- Stone Restoration: Restoring stone surfaces that have been weathered or damaged.

Public Works Sector

- Maintenance of Public Infrastructure: Cleaning and refurbishing surfaces on roads, bridges, and tunnels to ensure structural integrity and safety.

- Restoration of Public Buildings: Removing old paint, graffiti, and contaminants from government buildings, monuments, and statues to preserve their appearance and longevity.

- Monument cleaning: Removing dirt, grime, and weathering from statues and other outdoor structures.

- Water and Sewage Treatment Facilities: Cleaning tanks, pipes, and equipment to maintain optimal operation and hygiene standards.

- Public Transportation Systems: Preparing and cleaning surfaces of buses, trains, and transport infrastructure for maintenance and painting.

Food and Beverage Sector

- Cleaning Production Equipment: Removes product buildup and contaminants.

- Surface Preparation for Sanitation: Prepares surfaces for coating or sealing to meet hygiene standards.

- Maintenance of Storage Tanks: Cleans and removes rust or old coatings.

- Refurbishing of Machinery: Restores machinery to optimal condition, enhancing longevity.

- Facility Maintenance: Cleans floors, walls, and other surfaces to maintain a clean environment.

Marine Sector

- Hull Cleaning and Maintenance: Removing barnacles, algae, and other marine growth that accumulates on ship hulls.

- Surface Preparation for Painting: Preparing ship hulls and other marine structures for fresh coats of paint, by removing rust, old paint layers, and contaminants

- Removing Weld Spatter and Imperfections: Cleaning these areas, creating a smooth and even surface for further work or painting.

- Anchor Chain Cleaning: Cleaning anchor chains, restoring their functionality and ensuring smooth operation during deployment and retrieval.

- Tank Cleaning and Restoration: Cleaning and restoring cargo tanks on ships, by removing paint residue, rust, and contaminants

The Markley's Precision Difference

Expert Diagnosis

Customized Consultations

Beyond Standard Solutions

Transforming Surfaces into Masterpieces - Our Comprehensive Expertise in Commercial Sandblasting & Painting

With the right equipment and know-how, MPC contractors can blast it all. Surfaces become experiences thanks to us in commercial and industrial sandblasting and painting. Your project is a demonstration of potential rather than merely a duty. There is hardly a substrate we can’t work on, from sturdy surfaces like concrete and wood, through delicate materials like plastics and fiberglass, to the grace of natural stones and the refinement of vinyl asphalt.

Advanced Dry Blasting Solutions - Garnet Media and Dry Ice for Dust-Free, Efficient Cleaning

Need a low-dust blast in an area where equipment can’t get wet?

No problem!

High-quality garnet media blasting with a specialized dusting collector is an arsenal in our toolbox for quick and effective outcomes. But we don’t stop there; for jobs that require maximum cleanliness, we also employ the ground-breaking dry ice blasting method. This ensures a spotless workplace by producing zero dust and requiring little clean-up.

Sustainable, Fast, and Budget-Friendly Industrial and Commercial Blasting Solutions

But what if you’re also looking for a solution that’s sustainable, fast, low on dust, and friendly to your budget?

Believe it or not, you can have it all!

When it comes to industrial and commercial assets, we go the extra mile by involving our dustless blasting equipment, combined with 100% eco-friendly recycled crushed glass media or garnet – both are eco-friendly and derived from natural minerals.

Exceeding Standards - Precision Blasting for Impeccable Surface Finishes

Need a storage tank blasted to an SSPC SP5 with a surface profile of 2-3 mils?

Imagine a surface so flawless it’s a work of art. Our arms boast industry-leading DFT inspection equipment and premium-grade abrasives, enabling us not only to meet but surpass the rigorous standards of NACE, ISO, and SSPC commercial and industrial sandblasting specifications. But that’s just the beginning – we’re not just in the business of blasting but in the vicinity of crafting perfection.

Damage-Free Results - The Art of Precise Sandblasting

Will this damage…(insert blank)? The answer to this question is a resounding no.

The key to our success, then, is that blasting requires more than simply the right tools; it also requires knowledge. The alchemy of the perfect blast has been explored; choosing the precise blast media, such as crushed glass, garnet, dry ice, soda, plastic, or another material, will work wonders for your project.

We apply just the correct pressure, tailored to your unique substrate, and employ tactics that transform surfaces without a trace of damage.

ISO / NACE / SSPC Sandblasting Specs